Want to free up floor space and give a room a clean look with a pocket door frame? A correct install helps the door run smoothly and last longer. This post shows how to measure, prepare the rough opening, install the frame kit, fit the track, and adjust the hardware for quiet operation. Read the tips and checks to get the job done right.

A pocket door frame frees up floor area and streamlines room flow. This guide shows how to frame a pocket door, choose kits, and keep everything sliding smoothly.

Essential Benefits of a Pocket Door Frame

Space-Saving Design

A pocket door frame removes the swing arc, opening tight rooms like baths, closets, and pantries. You gain clear wall area for furniture or storage where a hinged leaf would collide.

Modern Interior Appeal

The clean pocket cavity and hidden track create a sleek look that fits contemporary spaces yet also suits traditional trim. For style ideas, browse this pocket door gallery and pick a door for pocket door frame that matches your trim package.

Enhanced Accessibility

With no swinging leaf to block movement, a pocket door frame eases access in narrow halls and small baths. For operation basics and clearances, see the ECLISSE installation guide that outlines smooth travel requirements.

Pre-Installation Planning and Required Measurements

Wall Type Assessment

Confirm whether the wall is load-bearing and scan for wires, plumbing, or ducts before cutting. A stud finder and inspection holes help you plan a safe cavity to frame pocket door hardware.

If you hit obstructions, consider rerouting lines or shift the opening; for odd sizes, look at custom size doors that fit your rough opening plan.

Cavity Requirements

The wall must offer clear space at least twice the door width so the panel can slide fully into the pocket. For a 36″ door, plan about 73″ of straight wall to avoid binding at the entry.

For planning tips on space and debris control, this complete guide on pocket door installation outlines site prep and layout checks.

Rough Opening Specifications

Set height as door height + 4.5″ and plan width as about 2 × door width + 1″ for pocket and jambs. Use shims to hit plumb and level so the track stays dead straight.

| Nominal Door Size (W × H) | Wall Width Needed (approx.) | Rough Opening Height |

|---|---|---|

| 24″ × 80″ | 49″ | 84.5″ |

| 28″ × 80″ | 57″ | 84.5″ |

| 30″ × 80″ | 61″ | 84.5″ |

| 32″ × 80″ | 65″ | 84.5″ |

| 36″ × 80″ | 73″ | 84.5″ |

Confirm your kit’s exact specs, since some tracks or soft-close units change the opening slightly. Accurate layout prevents rubbing inside the frame pocket door cavity.

Step-by-Step Guide: How to Frame a Pocket Door

Cut and Prepare the Rough Opening

Open the drywall to expose studs at the planned pocket, then mark layout lines for width and height. Remove only the studs required, and add temporary bracing to keep the wall stable while you work.

Build and Reinforce the Frame

Cut 2×4s for the king/jack studs and install a reinforced header across the opening to carry the load. Add blocking along the pocket to resist twist, which keeps the door travel true.

Level and plumb framing makes the difference between silky sliding and a door that drags.

Pro tip

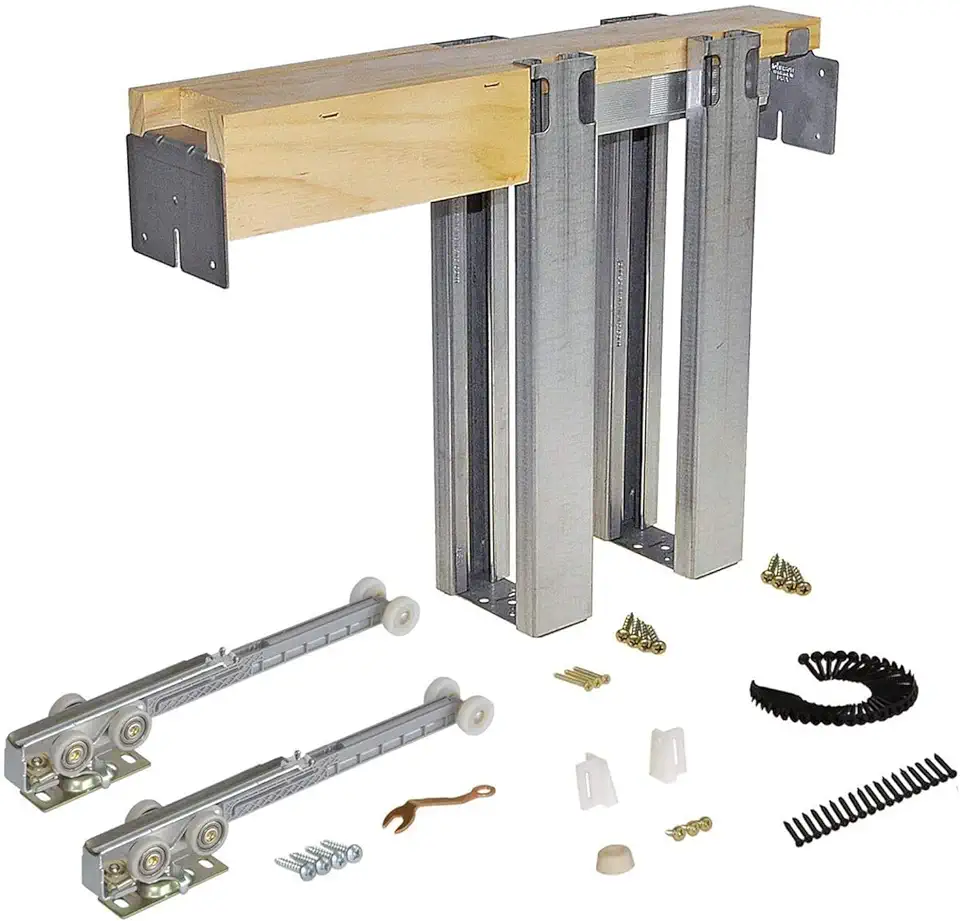

Install the Pocket Door Frame Kit

Set the pocket door frame into the opening, then shim side-to-side and vertically until it reads plumb and level. Fasten per the kit guide so the pocket stays square under trim and drywall.

For a photo-heavy walkthrough, see this Sawdust Girl tutorial that highlights shimming and fastening points.

Attach Track and Hardware

Mount the track to the header and screw rollers to the top of the door for pocket door frame. Install bottom guides at the floor or jambs so the panel can’t wobble inside the pocket.

Hang and Adjust the Door

Lift the leaf onto the track and clip the rollers in place; a helper adds safety. Use the roller adjustments to fix any tilt so the latch side closes flush.

Finish and Trim

Close up drywall, then sand and paint for a seamless wall. Add casing, soft-close units, and bumpers to cut impact noise and keep the operation gentle.

Expert Installation Tips for Pocket Door Frames

Safety Checks

Before you cut, map hidden systems and set up dust control for a clean site. Keep a fire extinguisher handy if you’ll use a recip saw near old wires.

- Scan with a stud finder and a voltage detector.

- Open small test holes to verify plumbing and HVAC paths.

- Wear eye, ear, and respiratory protection during demo.

- Support the ceiling with temporary studs if removing load-carrying members.

Kit Selection

Match the kit to wall thickness, weight rating, and door size. For a quick overview, this 6-step guide for beginners calls out common kit parts and roller types.

Measurement Accuracy

Recheck height, width, and jamb reveals before fastening anything permanently. Small layout errors compound and cause drag at the latch or inside the pocket.

Hardware Upgrades

Soft-close units and ball-bearing rollers make a big difference for daily use. If you need replacements, browse pocket door hardware that fits your track model.

Best Pocket Door Frame Kits and Systems 2025

These top-rated kits balance strength, quiet travel, and easy setup for a pocket door frame. Compare sizes, weight ratings, and soft-close options to fit your opening.

Johnson 1500 Soft-Close Pocket Frame 28×80

- Commercial-grade construction for heavy use

- Soft-close mechanism for smooth, controlled closing

- Designed to fit standard 2×4 stud walls

- Straightforward installation for contractors and DIYers

- Durable finish that resists wear and tear

JUBEST 36×80 Pocket Door Kit w/ 120lb Soft-Close

- 120lb soft-close system for reliable stopping power

- Fits doors from 24"

- to 36"

- for flexible use

- Galvanized steel studs add structural strength

- Hardware designed for easy DIY installation

- Smooth and quiet sliding performance

32×80 Half-Lite Frosted Glass Pocket Door Kit

- Half-lite frosted glass balances light and privacy

- Dual soft-close hardware for gentle, quiet closing

- Solid wood and MDF construction with white primer for easy finishing

- Pre-drilled panels speed up assembly

- Ideal for closets or interior room transitions

For heavy traffic, the Johnson 1500 is a strong value pick; pair it with your preferred handle and latch to complete the kit .

Maintenance and Common Troubleshooting

Annual Inspection

Vacuum the track and pocket to clear dust, then wipe rollers and guides with a dry cloth. A light silicone spray on the track helps keep motion quiet.

For reference on care and setup, the ECLISSE installation guide notes key service points you can check yearly.

Performance Issues

If the panel drags, check plumb at the jambs and tweak the roller height. Rubbing inside the frame pocket door often traces back to out-of-square framing or a bowed panel.

Hardware Adjustments

Re-tighten hanger bolts, guides, and stops, then test the soft-close catch. If parts are worn, swap in compatible kits from your blog recommendations or match items in manufacturer charts.

If framing loosens or drywall cracks, add screws at the pocket studs and re-square the jambs. For new openings or rebuilds, a complete exterior door frame kit shows how prebuilt systems save time even on interior projects with similar steps.

FAQs

How Do You Install A Pocket Door Frame?

Install a pocket door frame by first confirming the opening size and selecting a compatible kit. Remove existing trim and drywall where the pocket will go, frame the rough opening with a solid header and studs per the kit instructions, and install the pocket frame or metal track system level and plumb. Hang the door on the rollers, adjust the hangers so the door slides smoothly and is plumb, then reinstall drywall, trim, and hardware. Follow the manufacturer’s instructions closely and reinforce framing if needed for heavier doors.

What Is The Standard Size Of A Pocket Door Frame?

There isn’t a single standard size, but pocket door kits generally match common interior door sizes—24″, 28″, 30″, 32″ and 36″ widths with a standard 80″ height. The rough opening for the pocket is typically a couple inches wider than the door slab to accommodate the frame and sliding mechanism, and the wall depth must accommodate the pocket (about 3-1/2″ for a 2×4 wall or 5-1/2″ for a 2×6 wall). Always check the kit manufacturer’s specifications for exact rough opening dimensions.

Can Any Door Be Used As A Pocket Door?

Most interior slab doors can be converted to a pocket door, but not every door is ideal. Hollow-core doors are lightweight and often suitable; solid-core or heavy doors require stronger hardware and reinforced framing. Panel or moulded doors may need trimming to fit the pocket. Exterior doors, very heavy doors, or doors with ornate edges are generally not recommended. Verify door thickness and weight limits with the pocket hardware before installation.

How Do You Repair A Pocket Door Frame?

Start by diagnosing the problem—common issues are stuck doors, noisy rollers, bent tracks, or damaged framing. Remove the trim and door to inspect the track and rollers, replace worn or damaged rollers and straighten or replace the track as needed, then repair or sister any damaged studs or header members. Re-shim and square the frame, rehang and adjust the door, and patch drywall and trim. For structural damage or complex track/frame failures, consider replacing the pocket kit or hiring a professional.

What Are The Best Materials For A Pocket Door Frame?

Durable pocket systems use a combination of 2x framing lumber (or metal studs) for the wall structure and a steel track with nylon or sealed-bearing rollers for smooth operation. Metal pocket kits provide precise tracks and hardware; framing-grade lumber and plywood backing give solid support. For the door itself, a solid-core or high-quality hollow-core door balances weight and stability. In moisture-prone areas choose treated lumber or metal components to resist warping and corrosion.

Abdelbarie Elkhaddar

Glamorwood Ltd.

A door expert and home improvement writer with over 12 years of experience. I help homeowners and contractors choose smart, stylish, and secure doors.

Leave a Reply